As people’s demand for high-speed, stable, and large-capacity communications continues to grow, 5G technology has emerged. In 5G communications, RF antennas are key components, and their welding process faces unprecedented challenges and opportunities. Traditional manual welding methods are not only inefficient, but also difficult to ensure welding quality and stability under high-frequency and high-speed signal transmission, which is directly related to the coverage and communication quality of 5G networks. Therefore, the application of laser soldering technology is particularly important.

Table of Contents

ToggleThe Importance of 5G RF Antennas

The emergence of 5G technology not only brings higher data transmission rates, but also enables wider connectivity and lower latency. To achieve these goals, 5G RF antennas need to meet a series of stringent requirements.

5G communications use higher frequency bands, which requires antennas to have higher gain and directivity to ensure signal transmission quality. 5G networks need to support more antenna arrays to implement multiple-input multiple-output (MIMO) technology and improve data transmission rates and network capacity. Antennas also need to have better beam control capabilities and be able to flexibly adjust the direction of signal transmission and reception to meet communication needs in different scenarios.

Impact of Laser Soldering on 5G RF Antenna Performance

1. Improve welding accuracy

Laser beams have the characteristics of high energy, high precision and high directivity, which provide excellent conditions for the precision welding of 5G RF antennas. First, the laser beam can achieve the focusing of a very small spot, which can be accurate to the micron level, which enables extremely high precision when welding tiny RF antenna components. For example, when welding the fine connectors or tiny solder joints of the RF antenna, the accuracy and consistency of the welding position can be ensured.

Secondly, the energy distribution of the laser beam is uniform and controllable, which can achieve precise energy input to the welding area, avoiding excessive concentration or dispersion of energy, thereby ensuring the stability and reliability of welding quality. Furthermore, the laser beam can easily split the beam in time and space, and can perform multi-beam simultaneous processing and multi-station processing, which greatly improves the welding efficiency, especially for 5G RF antennas with complex structures, and can complete high-precision operations at multiple welding points at the same time.

2. Reduce heat damage

During the welding process of 5G RF antennas, thermal damage is an issue that needs to be paid special attention to. Laser soldering technology excels in this regard. Since the laser beam can quickly concentrate energy and achieve instantaneous heating and cooling, the heat-affected zone is effectively controlled within a very small range. This means that during the welding process, the thermal impact on surrounding sensitive components is greatly reduced. For example, when welding sensitive electronic components such as capacitors and inductors close to RF antennas, laser soldering can avoid performance degradation or damage caused by overheating.

At the same time, the precise energy control capability of laser soldering allows for flexible adjustment of welding parameters according to different welding materials and welding requirements, further reducing thermal damage. In addition, compared to traditional welding methods, the low heat input characteristics of laser soldering help reduce the formation of intermetallic compounds, thereby ensuring the electrical performance and signal transmission quality of the RF antenna.

Types of 5G RF Antennas Suitable for Laser Soldering

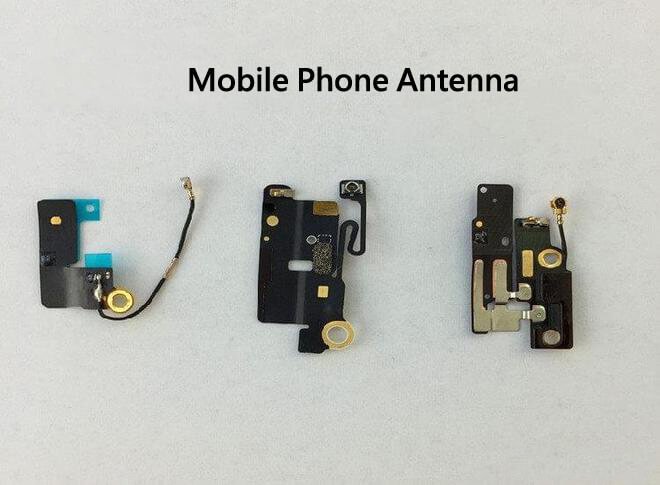

1. 5G Mobile Phone Antenna

As a representative of 5G mobile phones, Huawei Mate30 series has up to 21 antennas, 14 of which are used for 5G connections. This huge number of antennas means that 5G phones bring a significant incremental market for antennas.

In the manufacture of 5G mobile phone antennas, due to the limited internal space of the mobile phone, the precision and integration of the antenna are extremely high. The laser soldering process is very suitable for the welding of 5G mobile phone antennas due to its advantages such as high precision, non-contact welding and effective control of the heat-affected zone. For example, when connecting tiny antenna components, laser soldering can ensure the accuracy and consistency of the welding position, avoiding the thermal stress and deformation problems that may be caused by traditional welding methods, thereby ensuring the performance of the antenna and the quality of signal transmission.

2. 5G Base Station Antennas

The 5G base station circuit board coaxial antenna has extremely strict requirements for welding. Due to its complex structure and the need for high-frequency signal transmission, the solder joints need to have good conductivity, stability and low loss characteristics.

Laser soldering has significant advantages in the application of 5G base station antennas. It can achieve fast, accurate and reliable welding of antenna connectors, effectively improving welding quality and production efficiency. For example, when welding coaxial cables and PCB circuit boards, laser soldering can accurately control the welding temperature and time, ensure the consistency and stability of the solder joints, reduce signal transmission losses, thereby improving the performance and reliability of the antenna.

Finally

Laser soldering has significant advantages in the application of 5G base station antennas. It can achieve fast, accurate and reliable welding of antenna connectors, effectively improving welding quality and production efficiency. For example, when welding coaxial cables and PCB circuit boards, laser soldering can accurately control the welding temperature and time, ensure the consistency and stability of the solder joints, reduce signal transmission losses, thereby improving the performance and reliability of the antenna.